Skills Training

Bespoke, tailor-made programmes designed to enhance skillsets within the Engineering sector.

Skills Training

Bespoke, tailor-made programmes designed to enhance skillsets within the Engineering sector.

What are Skills Training Programmes?

Listed below are just a selection of the courses we provide. We pride ourselves very much on providing bespoke, tailor-made programmes, so if you don’t see what you are looking for, please get in contact using info@get-trained.org or the contact form at the bottom of this page, and we will be more than happy to discuss your requirements and develop a unique proposal for your business.

What are Skills Training Programmes?

Listed below are just a selection of the courses we provide. We pride ourselves very much on providing bespoke, tailor-made programmes, so if you don’t see what you are looking for, please get in contact and we will be more than happy to discuss your requirements and develop a unique proposal for your business.

To view our 2024 Commercial Training Calendar, please click here.

For any further information, please email info@get-trained.org or fill out our contact form below.

Explore Our Course Offerings

Our courses are 100% tailored to suit industry requirements. This means your learners are work ready from the minute they finish training.

Explore Our Course Offerings

Our courses are 100% tailored to suit industry requirements. This means your learners are work ready from the minute they finish training.

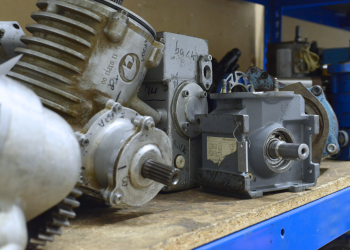

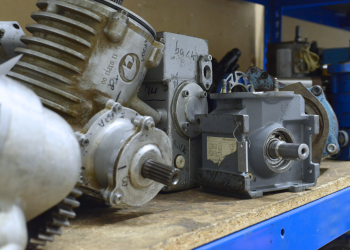

Machining

Learn more about the various Machining Skills Training Courses we have to offer. Flexible start dates and prices to suit any business.

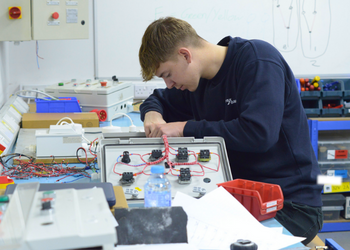

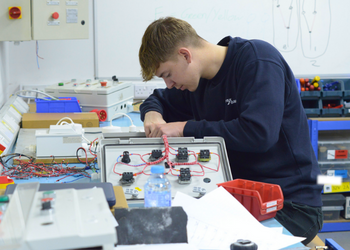

Electrical

Learn more about the various Electrical Skills Training Courses we have to offer. Flexible start dates and prices to suit any business.

Welding & Fabrication

Learn more about the various Welding & Fabrication Training Courses we have to offer. Flexible start dates and prices to suit any business.

Machining

Learn more about the various Machining Skills Training Courses we have to offer. Flexible start dates and prices to suit any business.

Electrical

Learn more about the various Electrical Skills Training Courses we have to offer. Flexible start dates and prices to suit any business.

Welding & Fabrication

Learn more about the various Welding & Fabrication Training Courses we have to offer. Flexible start dates and prices to suit any business.

Abrasive Wheels

Learn more about the various Abrasive Wheels Training Courses we have to offer. Flexible start dates and prices to suit any business.

Direct NVQ

Learn more about the various Direct NVQ Courses we have to offer. Flexible start dates and prices to suit any business.

Abrasive Wheels

Learn more about the various Abrasive Wheels Training Courses we have to offer. Flexible start dates and prices to suit any business.

Direct NVQ

Learn more about the various Direct NVQ Courses we have to offer. Flexible start dates and prices to suit any business.

Need Extra Help?

If you are interested in Skills Training and want to know more, please do get in touch with us via our contact form below.

*PLEASE NOTE* – By submitting you consent to our Privacy Policy.

Latest Skills Training News

Read the latest articles about GET, our apprentices/students and their respective employers.